Diving into the realm of replacement materials, this introduction sets the stage for an insightful journey into the world of innovative solutions for manufacturing and construction. From the significance of these materials in various industries to their environmental impact, this overview aims to provide a captivating glimpse into the evolving landscape of materials used in projects today.

Introduction to Replacement Materials

Replacement materials refer to alternative substances or components used in manufacturing or construction processes to substitute traditional materials. These alternatives are chosen based on their similar properties or capabilities to the original materials.

Utilizing replacement materials is crucial in various industries due to their potential to enhance efficiency, reduce costs, and address sustainability concerns. By opting for these alternatives, companies can achieve better performance, durability, and environmental benefits.

Importance of Using Replacement Materials

- Enhanced Performance: Replacement materials often offer improved characteristics such as strength, flexibility, or resistance, leading to better overall product quality.

- Cost Savings: Switching to alternative materials can result in reduced production expenses, lower maintenance costs, and extended product lifecycles.

- Sustainability: Choosing replacement materials can contribute to sustainability goals by reducing waste, energy consumption, and environmental impact.

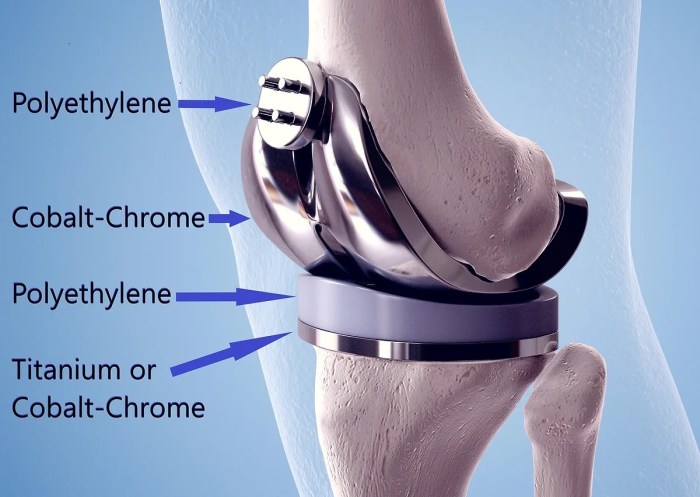

Types of Replacement Materials

When it comes to construction, there are various types of replacement materials that are being used to replace traditional materials. These replacement materials often offer improved properties and sustainability compared to their traditional counterparts.

Recycled Concrete

Recycled concrete is a popular replacement material for traditional aggregate in construction projects. It involves crushing old concrete into small pieces and using it as a base material for new construction. This not only reduces waste but also conserves natural resources.

Bamboo

Bamboo is increasingly being used as a replacement material for wood in construction due to its rapid growth rate and sustainability. It is strong, lightweight, and eco-friendly, making it an attractive alternative to traditional lumber.

Recycled Plastic

Recycled plastic is another innovative replacement material that is gaining popularity in construction. It can be used for various applications, such as decking, fencing, and even structural elements. This helps divert plastic waste from landfills and reduces the demand for virgin plastic.

Benefits of Using Replacement Materials

Incorporating replacement materials in projects offers a wide range of advantages, including cost savings and contributing to sustainable practices.

Cost Savings

Using replacement materials can lead to significant cost savings due to their lower price compared to traditional materials. This can result in overall project cost reduction and increased affordability for various construction or manufacturing projects.

Contribution to Sustainable Practices

Replacement materials often come from recycled or renewable sources, reducing the demand for new raw materials and minimizing environmental impact. By using these materials, projects can promote sustainability and reduce their carbon footprint, aligning with global efforts towards a greener future.

Challenges and Limitations

Implementing replacement materials comes with its own set of challenges that need to be addressed in order to ensure successful adoption. One common challenge is the availability of replacement materials in sufficient quantities to meet demand. This can be particularly difficult for niche or specialized materials that may not be widely produced.

Environmental Impact

One of the key limitations of certain replacement materials is their environmental impact. While some materials may offer benefits in terms of performance or cost, they may have a higher carbon footprint or generate more waste compared to traditional materials.

It is essential to consider the overall sustainability of replacement materials to ensure they are truly more eco-friendly.

Compatibility and Performance

Another challenge is ensuring that replacement materials are compatible with existing manufacturing processes and performance requirements. Some materials may not exhibit the same mechanical properties or durability as traditional materials, leading to concerns about product quality and longevity. Manufacturers need to carefully evaluate these factors when considering a switch to replacement materials.

Technological Advancements

Technological advancements are playing a crucial role in addressing these challenges and limitations. Through innovations in material science and manufacturing technologies, researchers are developing new materials that offer improved performance, reduced environmental impact, and better compatibility with existing processes. By leveraging these advancements, manufacturers can overcome the challenges associated with implementing replacement materials and unlock new opportunities for sustainable innovation.

Applications of Replacement Materials

Replacement materials have a wide range of applications across various industries, offering sustainable alternatives to traditional materials. These innovative materials are being utilized in construction, automotive, aerospace, and other sectors to improve performance, reduce environmental impact, and enhance cost-effectiveness.

Construction Industry

In the construction industry, replacement materials such as recycled concrete, reclaimed wood, and sustainable insulation are gaining popularity. These materials not only reduce waste but also contribute to energy efficiency and lower carbon footprint in building projects. For example, using recycled steel in construction can significantly decrease the environmental impact of new structures while maintaining structural integrity.

Automotive Sector

In the automotive sector, the use of lightweight materials like carbon fiber composites and aluminum alloys as replacements for traditional steel parts has become common. These materials help in reducing vehicle weight, improving fuel efficiency, and enhancing overall performance. Electric vehicles, in particular, benefit from the use of replacement materials to increase range and battery life.

Aerospace Applications

Replacement materials play a crucial role in the aerospace industry by offering lighter and more durable alternatives to conventional metals. Composite materials like carbon fiber reinforced polymers are widely used in aircraft manufacturing to enhance strength-to-weight ratio and fuel efficiency.

These materials are essential for creating advanced aircraft components that meet stringent performance requirements.

Future Trends

Looking ahead, the development and application of replacement materials are expected to continue growing to meet the increasing demand for sustainable solutions. Nanomaterials, bio-based composites, and 3D printing technologies are likely to shape the future of material science, opening up new possibilities for innovative applications across industries.

As research and development in this field progress, we can anticipate further advancements in material properties, cost-effectiveness, and environmental sustainability.

Conclusive Thoughts

In conclusion, the discussion on replacement materials unravels a tapestry of benefits, challenges, and future possibilities. As industries continue to embrace sustainable practices and innovative solutions, the role of replacement materials is set to reshape the way projects are approached and executed.

FAQ Corner

What are some common types of replacement materials used in construction?

Common types include recycled steel, reclaimed wood, and recycled glass.

How do replacement materials contribute to sustainable practices?

Replacement materials help reduce resource depletion and minimize environmental impact by utilizing recycled or alternative materials.

What are the challenges faced when implementing replacement materials?

Challenges may include higher initial costs, limited availability of certain materials, and the need for specialized knowledge in handling them.

Can replacement materials lead to cost savings?

Yes, using replacement materials can often result in long-term cost savings through reduced maintenance and energy expenses.